Controlling Barrel and Screw Wear is Critical

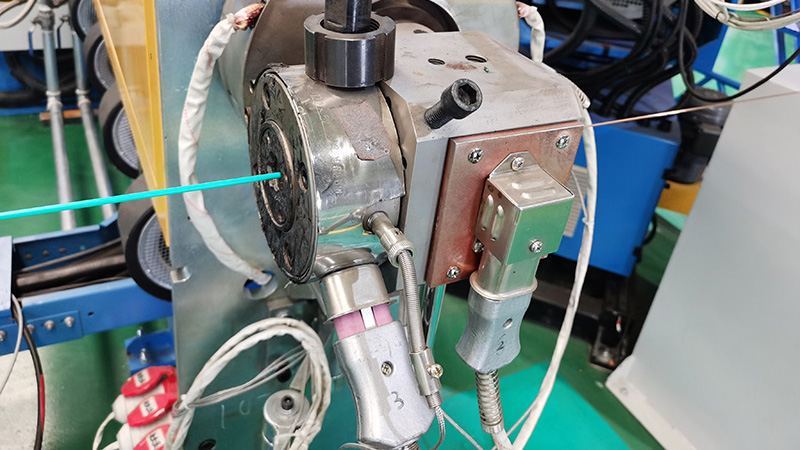

The premise that screw design is the most critical element in achieving the best melt for the process is only partially true. It is the entire plasticating unit that effectively melts, mixes and ultimately moves the flow through the die-head.

The material of construction is equally important to the specific design in achieving optimum screw design. We focus on both the materials and designs. To combat adhesive weal which is the first type of wear customers will experience on the barrel and screw, the IDM system is uniquely designed and materially compatible to slow file wear to almost zero. This is paramount to the effective use of the extruder and IDM barrel is Guaranteed.